Years ago I was hired to do some software work to improve the performance of a board sorting system in a sawmill. The PLC that controlled the system was such that any changes to the code required that the line be stopped, albeit briefly.

To me, this seemed like a small price to pay given the performance improvements that were being made. Any production shortfalls that were the consequence of these brief line stoppages would certainly be made up within a few days. What I had not noticed was the large reader board, which was installed above the line that displayed “board feet produced this shift”.

After the second or third time that I’d stopped the line to load a new program, I was roundly scolded by several of the plant’s operators: I was impacting their production this shift, as displayed on the reader board. After discussing the issue with them for a few mi nutes, they begrudgingly agreed to let me proceed. During the discussion, though, I came to understand that the value of this reader board to the operation was many times the cost of the component pieces.

nutes, they begrudgingly agreed to let me proceed. During the discussion, though, I came to understand that the value of this reader board to the operation was many times the cost of the component pieces.

If you ask them about their interest in keeping the numbers up as displayed on the board, the operators give a cerebral explanation: The more we produce per shift, the more profitable the plant will be, the more likely we are to keep our jobs, and the more money will be available for compensation. Underlying this conscious motivation, though, is a layer of emotion. The display promotes friendly competition from shift to shift and from day to day, and it becomes a point of pride when the numbers are good.

“Swing shift always has the highest numbers, even though we’re the most shorthanded…”

“Day shift almost always produces 10% more on days when I’m on…”

Since my experience in the sawmill, I’ve seen the same mentality in several other plants where production data is made visible in real time to the production staff. It’s truly a powerful motivator. I’ve also seen the opposite, where plant floor personnel are regarded as little more than cogs in a machine and are treated accordingly. In these plants, the level of concern about production hiccups is noticeably lower.

Provision of real time feedback for plant floor personnel is an integral component in sophisticated lean production systems. Such tools help promote thoughtful efforts by all members of the production team to reduce waste and improve efficiency. They can also be helpful in integrating the value chain, for example by displaying Takt Time.

the production team to reduce waste and improve efficiency. They can also be helpful in integrating the value chain, for example by displaying Takt Time.

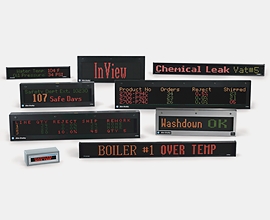

The value of real time feedback to the production floor is not lost on the major automation hardware vendors. For example, Allen-Bradley acquired a manufacturer of message displays a few years back and is now offering the displays as their InView line. These displays are ideal for communicating real time production data in Rockwell based automation systems.

More recently, Red Lion Controls announced the release of their ProducTVity Station™ device. This innovative product builds on Red Lion’s Data Station product line to extract production data from a vast array of different production systems and display the information on a standard HDMI display.

If your manufacturing facility isn’t presenting real time production data to the plant floor personnel, it probably should be.

If you’d like assistance selecting, designing or commissioning a plant floor data display system, please don’t hesitate to contact us.

509-551-8998